What is Stabilized Wood for Knife Handles: A Complete Guide 2025

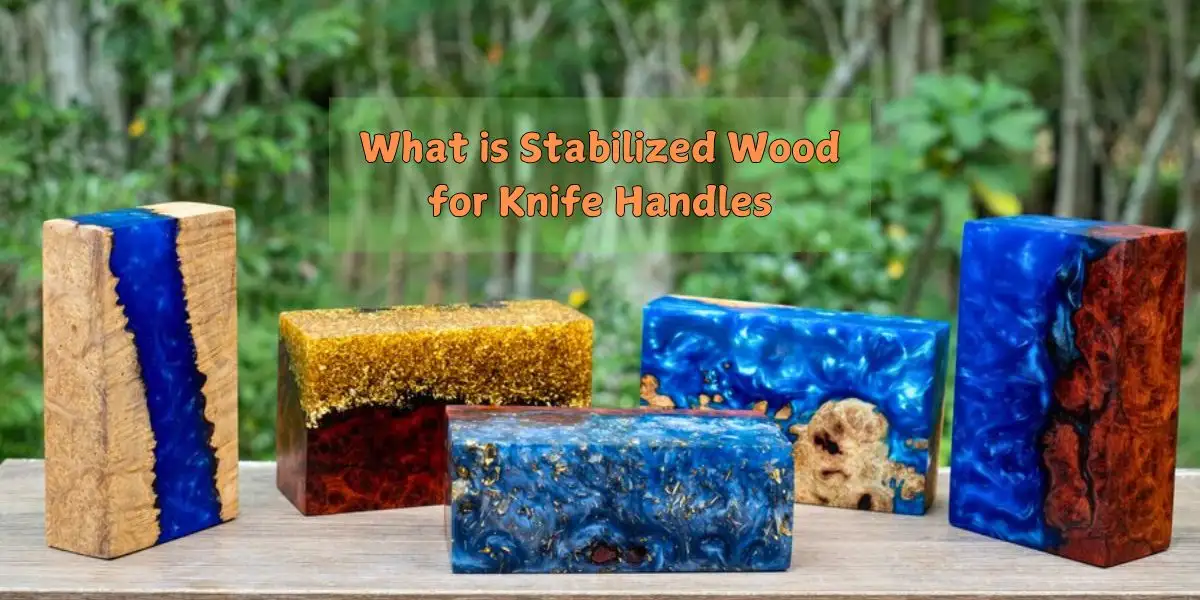

Welcome to the fascinating world of stabilized wood handles, where science meets craftsmanship. Every knife enthusiast knows a handle can make or break a blade’s performance. That’s where the magic of resin impregnation comes in, transforming ordinary low-density woods into extraordinary handle materials.

Think of birch, poplar, and beech handles—these once-humble woods now rival exotic materials like desert ironwood. Even delicate curly maple becomes incredibly durable through careful wood drying and preservation techniques. This isn’t just about making pretty handles; it’s about creating tools that last generations. The secret lies in moisture resistance and proper wood preservation.

Modern handle crafting has evolved into an art form where science enhances nature’s beauty. Whether you’re a professional knife maker or a passionate collector, understanding stabilized wood opens doors to endless possibilities. These handles aren’t just functional; they’re a testament to how far we’ve come in merging traditional woodworking with cutting-edge technology.

Understanding Stabilized Wood Basics

What Is Stabilized Wood

Stabilized wood is natural wood that’s been enhanced through a unique process. It’s like giving wood a superpower upgrade! The process fills all those tiny spaces inside the wood with strong resin, making the wood much stronger and more durable.

How Is It Different From Regular Wood

Regular wood can be tricky to work with. It moves, warps, and changes with moisture.

But stabilized wood stays put! Here’s why:

- Regular wood soaks up water like a sponge

- Unstabilized wood can crack and split

- Natural wood changes size with the weather

- Regular wood needs more maintenance

The Simple Science Behind It

The magic happens when liquid resin meets wood. Here’s the basic process:

- Wood is dried completely

- It’s placed in a vacuum chamber

- A special resin is forced into the wood

- Heat cures the resin inside

- The wood becomes permanently stabilized

Why It’s Perfect for Knife Handles:

Stabilized wood offers terrific dimensional stability. Unlike regular wood, it won’t shrink or swell. Exotic and figured woods look stunning after stabilization, and their natural patterns pop with fantastic clarity.

The difference between stabilized and unstabilized wood is like night and day.

Stabilized wood is:

- More durable

- Water-resistant

- Color-enhanced

- Longer-lasting

- Easy to maintain

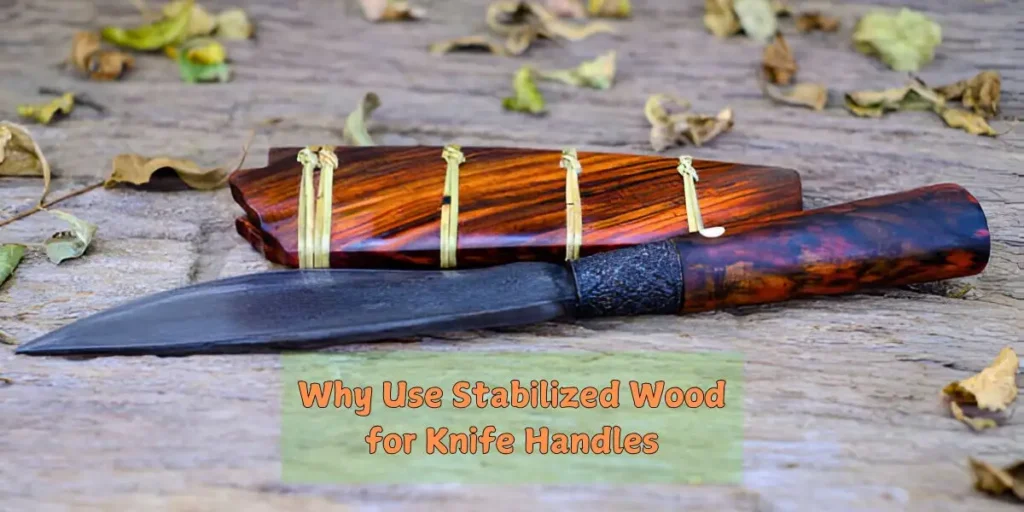

Why Use Stabilized Wood for Knife Handles

Game-Changing Advantages

Stabilized wood is in a league of its own regarding knife handles. Its dimensional stability makes it incredibly reliable for daily use. Unlike regular wood, which shifts and changes, stabilized wood maintains its shape perfectly. This is especially important when working with exotic and figured woods, as their natural beauty is preserved forever.

Perfect Wood Selection

The magic of stabilization works best with specific types of wood. Low-density woods are ideal candidates because they readily accept the stabilizing resin. After treatment, birch handles transform from decent to outstanding. Similarly, poplar handles become remarkably sturdy, while beech handles develop exceptional durability. The unstabilized wood comparison shows just how dramatic this improvement can be.

Value That Lasts

Sure, stabilized wood costs more initially, but its value becomes apparent over time. Your knife handle will maintain its shape and beauty for years, requiring minimal maintenance. The colors stay vibrant, and the wood remains strong regardless of weather conditions. This durability makes it perfect for everyday kitchen knives and specialized hunting tools.

Professional Choice

Professional knife makers choose stabilized wood for a good reason. It offers consistent performance and outstanding durability while maintaining the wood’s natural beauty. Each piece tells its own story through unique grain patterns and colors. The enhanced strength means your knife handle will feel solid and secure for years to come, making it an investment worth every penny.

The Science Behind Wood Stabilization

Understanding the Process

The wood stabilization process is fascinating yet straightforward. It starts with carefully selecting the best woods for knife handles. These woods must be completely dry before treatment begins. Think of it like preparing a sponge to soak up water—except we’re using special resin instead. The wood enters a vacuum chamber, where all the air is pulled out from its tiny pores.

The Magic of Stabilization

Wood stabilization methods have evolved, but the basic principle remains the same. Once the vacuum removes all air, stabilizing resin floods the chamber. The vacuum pressure forces this resin deep into the wood’s cells. It’s like watching a dry sponge drink up water, but much slower and more controlled. This process can take several hours to ensure complete penetration.

Chemical Magic at Work

The chemistry makes all the difference when comparing stabilized and unstabilized wood. As the resin seeps into the wood, it replaces all the air spaces. Then comes the heating phase. The wood and resin are heated to specific temperatures, usually around 200 degrees Fahrenheit. This heat triggers a chemical reaction that permanently hardens the resin inside the wood.

Final Transformation

The result is remarkable. The once-porous wood becomes solid and dense, and its colors become more profound and vibrant. The wood’s surface feels smoother and more complex. Most importantly, it won’t shrink, expand, or crack anymore. This transformation creates a material perfect for knife handles—beautiful, durable, and stable in any environment. The whole process turns ordinary wood into something extraordinary, ready to become part of a cherished knife handle.

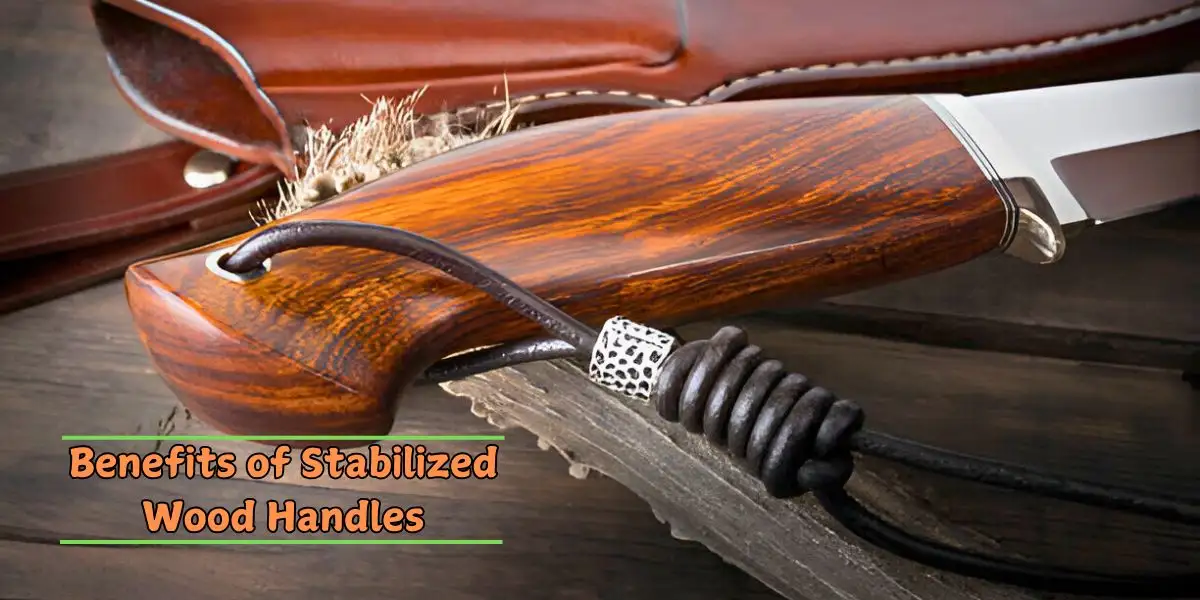

Benefits of Stabilized Wood Handles

Practical Advantages

Let’s discuss why stabilized wood handles are such a game-changer. First, they laugh in the face of moisture. While regular wood soaks water like a sponge, stabilized wood stays dry and firm. This moisture resistance means your knife handle won’t swell during humid summer days or shrink when winter comes. The dimensional stability is simply excellent—your handle will keep its perfect shape year after year.

Built to Last

Regarding durability, stabilized wood handles are in a league of their own. They can take a beating that would destroy regular wood handles. Even better, they handle temperature changes like a champ. The handle stays strong and comfortable whether you use your knife in a hot kitchen or the cold wilderness. This toughness means your knife will serve you faithfully for years to come.

Beauty That Stops People in Their Tracks

Now, let’s talk about looks because stabilized wood handles are stunning. The stabilization process enhances the wood’s natural colors, making it more profound and vibrant. Every grain pattern and natural figure in the wood becomes more pronounced. It’s like turning up the volume on wood’s natural beauty. The finishing possibilities are endless, too. You can polish these handles to a mirror shine or give them a subtle, sophisticated matte finish.

Long-Lasting Beauty The best part?

This beauty isn’t just skin deep. Unlike regular wood that can fade or dull over time, stabilized wood handles keep their gorgeous looks for years. The colors stay rich, the patterns remain crisp, and the finish holds up beautifully. It’s like having a piece of fine art that you can actually use every day.

Best Woods for Stabilization

Choosing the Perfect Wood

Let’s explore what makes certain woods perfect for stabilization. Hardwoods and softwoods each offer something exceptional. Hardwoods like maple, birch, and oak provide excellent strength and beautiful grain patterns. Softwoods can work, too, but they need extra care during stabilization. The key is finding woods with the right natural properties that will accept the stabilizing resin well.

Top Wood Choices

Among the most popular species, maple stands out as a superstar. It takes to stabilization beautifully and creates stunning handles. Burl woods are favorites because their unique patterns become even more dramatic after stabilization. Box elder, buckeye, and spalted woods also make gorgeous handles. These woods have the perfect balance of density and porosity to accept stabilizing resin while maintaining their character.

What to Watch Out For

Not all woods are suitable for stabilization. Very dense woods like cocobolo or ebony resist stabilization because they are too tight-grained. Oily woods like teak can be problematic, too—their natural oils prevent proper resin penetration. Woods with large, open-grain patterns might need multiple stabilization cycles, driving up costs.

Smart Selection Tips

Cost-effectiveness plays a significant role in wood selection. Some exotic woods might look amazing, but their high price tag makes them impractical for most projects. The best approach is to choose moderately priced woods that stabilize well. Look for woods with consistent grain, no significant defects, and moderate density. This ensures you get beautiful results without breaking the bank. Remember, even simple woods can become extraordinary after proper stabilization.

Choosing Quality Stabilized Wood

Spotting Top Quality

When looking at stabilized wood, your eyes are your first tool. Quality stabilized wood shows consistent color throughout, with no dull or cloudy spots. The grain patterns should be clear and well-defined. When you hold it up to light, you shouldn’t see any areas that look different. The surface should feel smooth and solid, without soft or sticky patches.

Physical Testing

Made Simple Good stabilized wood has distinct physical properties. It should feel heavier than its unstabilized counterpart. Try tapping it gently – you should hear a solid, higher-pitched sound rather than a dull thud. Run your fingernail across the surface. Quality stabilized wood resists scratching and feels consistently tricky everywhere. The wood shouldn’t feel tacky or have any areas that feel different from others.

Warning Signs to Watch

Poor stabilization leaves telltale signs. Watch out for pieces with varying colors or patches that look lighter than others. If you see any areas that feel softer or spongier, that’s a red flag. Avoid pieces with visible gaps or voids in the wood. These defects mean the stabilization process wasn’t complete, and the handle wouldn’t perform well over time.

Price and Quality

Balance Don’t let price alone guide your choice. Super cheap stabilized wood often means corners were cut during the process. However, extremely high prices don’t always guarantee better quality. Look for reasonably priced pieces that show all the right quality indicators. A good stabilized wood piece should feel solid, look uniform, and have a price reflecting the quality of the wood and the stabilization process.

Care and Maintenance of Stabilized Wood Handles

Daily Care Essentials

Taking care of your stabilized wood handle is surprisingly simple. After each use, a quick wipe with a soft, dry cloth is usually all it needs. If your handle gets dirty, use a slightly damp cloth with mild soap, then dry it thoroughly. Unlike regular wood, you don’t need special oils or treatments. The stabilization process has already protected the wood from within, making daily maintenance a breeze.

Smart Storage Solutions

Proper storage helps preserve the beauty of your knife’s handle. Keep it in a knife block or sheath away from extreme temperatures. While stabilized wood handles are rigid, they’ll last even longer if you avoid leaving them in direct sunlight for long periods. A cool, dry place is perfect. Never store your knife in damp conditions, even though the handle is moisture-resistant.

Long-Term Care

Secrets: Your stabilized wood handle will develop character over time but won’t deteriorate like untreated wood. The colors might be slightly mellow, creating a beautiful, aged look. Light buffing with fine-grit sandpaper can restore its surface if your handle gets scratched. Deep scratches might need professional attention, but they’re rare thanks to the handle’s durability.

Environmental Protection

While stabilized wood handles are incredibly resilient, extreme conditions can still affect them. Avoid leaving your knife in cold or intense heat for long periods. The handle won’t warp or crack, but keeping it in moderate conditions ensures it stays beautiful longer. With proper care, your stabilized wood handle will maintain its stunning appearance and solid performance for many years.

Cost Analysis of Stabilized Wood

Understanding the Price Range

When shopping for stabilized wood, prices vary considerably. Entry-level pieces start around $20, while premium blocks can reach $100 or more. These prices reflect the quality of the original wood, the stabilization process, and the final product’s beauty. Common woods like maple or birch cost less than exotic burls or rare-figured woods. The size and quality of the piece also affect the price, with larger, defect-free blocks commanding higher prices.

Value vs. Alternatives

Compared to other handle materials, stabilized wood might initially seem expensive. However, its durability and beauty make it a wise long-term investment. Synthetic materials like G10 or Micarta cost less but lack the natural beauty of wood. Traditional unstabilized wood handles are cheaper upfront but need more maintenance and don’t last as long. When you consider the lifetime value, stabilized wood often proves more economical.

Finding Reliable Sellers

The best places to buy stabilized wood are specialty knife-making suppliers and established woodworking shops. These vendors understand quality and typically offer guarantees. Online marketplaces like Etsy or specialized knife-making websites can be excellent sources, but research the seller’s reputation first. Local woodworking stores might stock stabilized wood, offering the advantage of examining pieces in person before buying.

Smart Shopping Tips

Ask about the stabilization process and wood origin, whether online or locally. Good vendors freely share this information and often provide certificates of quality. Look for sellers who offer clear photos and detailed descriptions of their products. Many reputable vendors also provide customer support and accept returns if the wood doesn’t meet expectations. Building a relationship with a trusted supplier can lead to better prices and access to premium materials.

Practical Applications in Handle Making

Selecting Perfect Woods

The journey starts with choosing the right wood. After stabilization, low-density woods like birch, poplar, and beech make excellent handle materials. These woods readily accept resin impregnation, creating incredibly durable handles. Desert ironwood and curly maple offer stunning grain patterns, though they need careful drying before treatment. The stabilization process enhances their natural beauty while ensuring perfect wood preservation.

Kitchen to Wilderness

Stabilized birch handles excel in the kitchen due to their moisture resistance and comfortable grip. Hunting knives often feature desert ironwood or beech handles because they withstand harsh outdoor conditions. Curly maple’s eye-catching patterns make your knife stand out for everyday carry knives. Custom knife makers love mixing different woods, combining poplar’s light tone with darker species for a striking contrast.

Getting Started Right Handle crafting begins with proper preparation. Each wood type requires specific attention—birch handles require careful shaping, while desert ironwood requires extra time during stabilization. The resin impregnation process must be complete and uniform. For beginners, professional makers often prefer beech handles due to their predictable installation behavior.

Installation Success

Proper installation is crucial whether you’re a DIY enthusiast or a professional maker. The wood must be completely stable before working. Moisture resistance comes from proper resin saturation, so checking for complete stabilization is essential. Each wood type has its quirks.

Poplar handles need careful pressure during mounting, while curly maple requires extra attention to grain direction. Understanding these characteristics ensures your handle will last for years.

Conclusion

Today’s Excellence Due to resin impregnation, stabilized wood handles have forever transformed knife-making. Low-density woods like birch, poplar, and beech now rival premium materials. The perfect marriage of wood preservation and craftsmanship creates handles that last generations. Desert ironwood and curly maple showcase nature’s beauty while offering incredible durability.

Tomorrow’s Promise: The future looks bright for handle crafting. New techniques in wood drying and stabilization keep emerging. Moisture resistance continues to improve, making these handles even more reliable. The growing popularity of custom knives drives innovation in wood preservation methods. Makers are pushing boundaries, combining different woods and techniques for stunning results.

Smart Choices For beginners, start with stabilized birch handles – they’re forgiving and beautiful. More experienced crafters might explore desert ironwood’s challenging but rewarding character. Remember, proper stabilization matters more than wood choice. Whether you’re a professional or an enthusiast, understand each wood’s properties. Your perfect handle awaits in this exciting world of stabilized wood.

FAQs about stabilized wood for knife handles

With basic care, an adequately stabilized wood handle can last decades, while regular wood handles might need replacement in 5-10 years. The resin impregnation makes these handles highly resistant to moisture, wear, and environmental damage.

Yes, stabilized wood handles can safely get wet. Unlike regular wood, they won't absorb water or swell because the resin fills all the wood's pores. To maintain their appearance, just wipe them dry after exposure.

Yes, they're worth the investment. While stabilized handles cost more upfront, they require minimal maintenance, last longer, and maintain their beauty better than untreated wood. They also add value to your knife.

While possible, home stabilization requires specialized equipment, such as a vacuum chamber and careful handling of resins. Most experts recommend buying pre-stabilized wood or working with professional stabilizers for the best results.

Properly stabilized wood feels heavier than usual, has a consistent color throughout, and makes a higher-pitched sound when tapped. It shouldn't feel soft in any spots or show varying density when tested with a fingernail.

Stabilized maple or birch are excellent choices for kitchen knives. They offer good grip when wet, resist food stains, and have enough density to withstand daily use while remaining comfortable.

Minor scratches can be buffed out with fine sandpaper and polished. However, severe damage usually requires professional repair or handle replacement since the stabilization process can't be repeated on already stabilized wood.

Related Posts

-

23 Feb 2025 KnifeWhat Is a Slicing Knife Used For? Discover How It Makes Cooking Easy!

23 Feb 2025 KnifeWhat Is a Slicing Knife Used For? Discover How It Makes Cooking Easy! -

16 Feb 2025 KnifeWhat knives does Gordon Ramsay use? Check out his premium knives

16 Feb 2025 KnifeWhat knives does Gordon Ramsay use? Check out his premium knives -

15 Feb 2025 KnifeWhat Knife Do Navy Seals Use? SEAL's Standard Issue 2025

15 Feb 2025 KnifeWhat Knife Do Navy Seals Use? SEAL's Standard Issue 2025 -

08 Feb 2025 KnifeWhat Knife Does John Wick Use? Learn About His Deadly Blade

08 Feb 2025 KnifeWhat Knife Does John Wick Use? Learn About His Deadly Blade -

30 Jan 2025 KnifeWhat is a Nakiri Knives Used For? Benefits & Features Explained

30 Jan 2025 KnifeWhat is a Nakiri Knives Used For? Benefits & Features Explained -

12 Jan 2025 KnifeFish Knife vs Butter Knife: Key Differences and Uses Explained

12 Jan 2025 KnifeFish Knife vs Butter Knife: Key Differences and Uses Explained -

11 Jan 2025 KnifeHow to Sharpen Global Knife: A Quick Guide 2025

11 Jan 2025 KnifeHow to Sharpen Global Knife: A Quick Guide 2025 -

10 Jan 2025 KnifeDecoding the Iconic Why So Serious Joker Knife

10 Jan 2025 KnifeDecoding the Iconic Why So Serious Joker Knife -

09 Jan 2025 KnifeThe Right Way to Use a Steak Knife: Tips and Tricks

09 Jan 2025 KnifeThe Right Way to Use a Steak Knife: Tips and Tricks -

08 Jan 2025 KnifeHow to Sharpen a Morakniv Knife Safely and Effectively

08 Jan 2025 KnifeHow to Sharpen a Morakniv Knife Safely and Effectively